All posts by Joe Rider

Why is Cleaning One of the Most Important Aspects of the Bio Security Process in Agriculture?

As you consider your many responsibilities for bio-security in the agricultural field, one factor to consider is cleaning. But why is it so important? You likely know the obvious reason but there are some surprise benefits that you may not be aware of. Keep reading to learn about them and then contact Pressure-Pro at 772-461-4486 to learn about solutions to cleaning problems.

Focus on Cleaning Both Indoors and Outdoors

When you are working to clean and disinfect your farm, make sure you are considering everything both inside and outside. This includes all vehicles you use on the farm, all transport vehicles, and all waste disposal equipment. For example, wash plates should be placed in an effort to ensure that the disinfection of tires is done on both incoming and outgoing vehicles.

You should place wash bays and wash areas away from your livestock areas. This helps prevent contamination that could otherwise be caused by spray if the wind works just right. Each time you are done loading and unloading animals, the vehicles used should be thoroughly cleaned

Route Cleaning Prevents Buildup

When you clean the routes between buildings, you can help to avoid the buildup of waste, dirt, and animal feed – all of which could attract vermin and even dangerous feral animals. If you engage in regular, mechanical, high-quality cleaning practices with the right products, you can lower the risk of contamination by wild animals.

Separate Black from White Areas

One of the most helpful ways to think of your cleaning is to separate needs into black and white areas. Then use different cleaning equipment for each white and black area, use disinfection mats and hygiene sluices between these zones and between these entrances. Always lean the white areas before the black, and leave all the tools and equipment you used in the right zone.

White areas include:

- Walls

- Showers

- Floors

- Locker rooms

These can be cleaned with steam cleaners and wet and dry vacs.

Black areas include:

- Changing rooms

- Administration areas

- Sties

- Barns

- Stables

For these areas, use high-pressure washers, small floor care, and detergents.

The cialis generic prolongator contains a powerful remedy for tadalafil and dapoxetine, which prolongs sexual intercourse.

Indoor Cleaning is Essential Too

Of course, cleaning indoor areas is essential too. Pressure washing helps keep indoor areas hygienic too. This can include poultry barns, egg facilities, animal sheds, pigsties, and other areas. Create special vehicle and equipment cleaning areas outside of the buildings they will be stored in. Use hot water to help eliminated bacteria and germs.

Do You Have Questions About Pressure Washing Equipment?

If you have questions about what pressure washing equipment would be best for your needs, we strongly recommend you contact Pressure-Pro at 772-461-4486 . With years of experience, we are standing by to get you the answers you need to get the products you want.

These Are the Focus Areas for Improving Bio Security and Reducing Risks in the Agricultural Industry

One of the reasons it is often so intimidating to find ways to boost bio-security and reduce risks for those in the agricultural industry is the fact that many people simply do not know where to start. That is why Pressure-Pro is here to present the focus areas you can look at to help reduce your risks and stay safe in these difficult times.

Keep Farms and Livestock Areas Separate

Your livestock areas and farm area must be kept far away from each other. At a minimum, make sure you are meeting local recommend distances between livestock areas and breeding areas. This is essential for safety, cleanliness, and hygiene.

Consider Natural Water Sources

It may seem good to have a natural water source on the property, but consider that this water source can attract wild animals and birds. This can cause contamination in many different ways, especially if you are dealing with free-range breeding on your property.

You Must Have Separate Routes for Ingoing and Outgoing

Your farm layout must have ramps and line connections specifically for loading, and unloading areas that allow you to avoid direct contact with vehicles and other sensitive zones. When you engage in deep cleaning, do so separately for ingoing and outgoing routes so that they do not contaminate each other.

Ensure Clear Zones to Separate Controlled Access Zones and Restricted Zones

If you have different zones at your farm, such as zones that are only accessible to employees and zones that are restricted to owners only, it is important that you keep these areas completely separate from one another. This requires clear lines of separation with different gates, fences, and more. Good gates and fences can also ensure that wild animals cannot enter your property.

Vehicle Washing Stations Should Be Set Up Away from Livestock

One of the most common ways that an agricultural site can become infested is via vehicles that come and go from the site. We recommend a vehicle washing area that is located away from the livestock. This helps to greatly reduce the chance of wind-born droplets getting to barns, sheds, and other areas that could result in livestock access.

Verify Feed, Bedding, and Water

You likely looked into the feed, bedding, and water you use when you decided on a purveyor, but when is the last time you have inspected supplier certifications? Now is a good time to verify them and ensure that you are still working with the best vendors in the area.

When it comes to sanitization vendors, remember that choosing the right pressure washer and pressure washer equipment is an important part of keeping your agricultural site safe. If you need help deciding on what to invest in, you can contact Pressure-Pro at 772-461-4486 for an honest assessment.

Learn the Most Common Bio Security Risks and Where They Come From

Most companies who have high bio-security risks have those risks not because they do not care about their workers or customers but because they are not sure where the risk or are what to do about them. At Pressure-Pro we have outlined the key biosecurity risks so you can protect your business, your workers, and your family. Then contact us at 772-461-4486 to learn how pressure washers can help you reduce or eliminate these risks.

Transferring Animals from One Area or Site to Another

Anytime you are transferring animals from one place to another, you are running a risk. Why? Because if one or more of those animals are diseased, they could be passing their disease on to all the animals in the new area. That is why a good biosecurity plan focuses not just on preventing disease in the first place but on preventing the spread of that disease as well.

Dead Animals

No matter how an animal dies, it can pass disease after its death. This could be the disease that killed it, an underlying disease you were not aware of, or disease from another animal or parasite that takes advantage of the dead animal. These are just a few of the reasons that you should remove dead animals as soon as possible and thoroughly sanitize the area in which they died.

Wild Animals and Vermin

If your facility has an infestation of wild animals, rodents, or insects, they can bring disease with them. In fact, this is how the black plague was most likely transferred from one person to another. Again, a good biosecurity plan cannot be limited to keeping things clean – it must also include ways to keep undesirables of all types away from the animals.

People

Of course, people who come onto your farm are a risk as well. This can be your staff, visitors, or vendors. If possible, create pickup and drop-off spots so vendors can drop off items without coming onto your farm. Create a specific and required protocol for your staff to wash their hands and sanitize before they come into contact with the animals.

Vehicles and Other Equipment Coming from Other Sites

If you share equipment with a nearby farm, it may make sense on a financial level but could also be putting your entire operation at risk. If the farm you share the equipment with becomes contaminated, that contamination could come to your farm via that machinery. This is true of trucks and other vehicles too.

The Key is Thorough Cleaning Practices

If you want to keep your operation as safe and secure as possible, we strongly recommend creating and sticking to specific protocols that can help you through even the worst epidemic. Contact Pressure-Pro at 772-461-4486 if you need help finding the right power washing equipment for this purpose.

Following These Simple Eight Steps Will Eliminate or Significantly Reduce Germs on Poultry Farms

There may never have been more discussion of the germs that can live and spread in poultry farms. At Pressure-Pro we know that farmers want to find ways to protect their workers, their industry, and their customers. By following these simple eight steps, you can eliminate or, at a minimum, significantly reduce germs on your farm.

- Have a Plan

Before you begin, look at your surroundings. Look at the dirt and bacteria you are cleaning. Ask yourself if you will be able to use hot water pressure washers, or if another type of specialty pressure washer will be needed. Consider the disinfectants and cleaners you will need to get the job done the way you want it done. - Determine the Right Cleaning Pressure

No two jobs are identical. Depending on the surfaces you are cleaning, the amount of dirt and other grime you are dealing with, will determine the right pressure level to get rid of everything. - Determine the Right Temperature

The hotter the water is, the more bacteria and germs it can kill. As the water gets hotter, germs will begin to breakdown. Generally speaking, temperatures of 185 – 212 F can make a big difference in the amount of bacteria colonies, but you will need temperatures of up to 311 F to get rid of germs entirely. - Choose the Right Detergent

You will need a detergent that is complementary to the job you are trying to do. You will also need to consider local and statewide recommendations on what ingredients should be avoided. Once you have chosen your detergent, soak the surface with it to break down any tough-to-kill layers of dirt and waste. - Rinse the Surface

After the detergent has had time to soak in, rinse the surface off with hot water or steam. Get rid of as much dirt and waste as you possibly can. Certain units can heat water to 284 degrees F, which vaporizes the water for wet steam pressure washing. This can work toward sterilization of the surface. - Apply Your Disinfectants

Cleaning is important but it is not enough to get the surface entirely disinfected. Choose the right disinfectant while keeping in mind the type of surface you are cleaning, the type of bacteria you want to eliminate, and local and statewide rules. - Choose the Right End-Tools

Depending on the job, you may need additional accessories such as lances, sprayers, and nozzles. If you are not sure what is required for your particular job, contact Pressure-Pro at 772-461-4486 and let us help you. - Let the Surface Dry

Leave the surface to dry completely. Do not open it up to new livestock or even human passage until it is dry. If you do so, you will be risking hygiene and safety issues.

These are the top eight tips we have to get your poultry farm as sanitized as possible. Do you have questions about the process or how to get the right equipment? Call Pressure-Pro at 772-461-4486 for help.

Bio-Security in Agriculture: You Don’t Have to Choose Between a Sanitary Operation and Sustainability

Too often, those who run agricultural operations assume that they have to make difficult decisions that don’t actually need to be made. For example, if you are under the mistaken impression that you have to decide if you want your property to be sanitary or if you want to follow sustainable practices, you are in for good news: Hot water pressure washing can give you both.

Lower Resource Consumption Makes Hot Water Pressure Washer Use Sustainable

Most people wash their dishes with hot water – and for a good reason. This is the best way to get dishes as clean as possible as quickly as possible. The same is true of hot water pressure washer usage. If you use hot water, you will get the surface area cleaner faster than you would with a cold water pressure washer.

How much faster? According to one test we conducted with the Cleaning Technology Institute, hot water lowered cleaning times by an average of 40% across the board. When the surface was greasy or oily, hot water cleaning was as much as four times as efficient compared to cold water. This means a 75% drop in cleaning time.

Get Back to Work More Quickly with Hot Water

Not only does hot water get the surface clean much more quickly, but it also dries faster. Some surfaces, such as certain types of flooring, must be 100% dry before you can allow workers or customers to walk on them. If they are washed with hot water, they will be dry much faster than if they are washed with cold water. The same is true no matter the surface, whether it’s the side of your property or the handles of grocery carts.

Use Less Water with the Right Pressure Washer

When you use the right pressure washer for the job, you use less water. Why? Because you clean faster and the faster you clean, the less water you use. Consider that, on average, for every 264 gallons of water needed with a cold water pressure washer, hot water pressure washers can save around 106 gallons.

Use Less Energy with the Right Pressure Washer

Just as you will use less water if you are using your washer for less time, you will also use less energy. This is true whether you have a gas-powered pressure washer or an electric-powered pressure washer. Reduce your expenses and your carbon footprint by using the right pressure washer.

Use Fewer Chemicals

It is often the case that using hot water is all that’s need to get rid of dirt and other grime. If you are sanitizing and disinfecting you will want to use a product for that, but still – reducing the cleaning chemicals is a step in the right direction.

To find out more about how to find the right pressure washer for your needs, contact Pressure-Pro at 772-461-4486 to learn more.

Bio-Security in the Time of COVID-19: Learn Why Pressure Washing Should Be an Integral Part of Your Plans

Companies are doing everything they can to survive the necessary changes that have been made as a result of COVID-19. At Pressure-Pro, we offer a wide range of pressure washing options that are essential as part of your bio-security response to COVID. Continue reading to discover why pressure washing is so important and then contact us at 772-461-4486 to learn more.

It is Essential to Clean More, Clean Faster, and Clean More Efficiently

Any bio-security response that involves cleaning should likely involve pressure washers. Using pressure washers allows you to clean more surfaces, to clean those surfaces faster, and to clean those surfaces more efficiently. It doesn’t matter if you are cleaning floors, shopping carts, or agricultural equipment, you can trust that hot water is one of the most important tools you have.

Enjoy Three Big Benefits When You Use Hot Water Cleaning

When you choose hot water pressure washers, you can enjoy three main benefits:

- Efficient, better, and faster cleaning results

- Reduced bacteria and virus counts, along with better overall hygiene

- Lower resource consumption compared to other cleaning methods

Think of it like this: Do you clean your dishes at home with hot water or cold water? If you are like most people, you use the hottest water you can stand because it simply cleans faster and better.

Hot Water Can Reduce Cleaning Times by As Much as 40%

We worked with the Cleaning Technology Institute to test both hot and cold water pressure washers. While cold water pressure washers have their applications, across all applications hot water reduced cleaning times. On average, the reduction was about 40% but in other cases, specifically those that involved oils, hot water cleaning was four times as effective for a total reduction of 75% of cleaning time.

Not only do your surfaces get cleaner, but the hot water helps lower the time said surfaces need to dry, which means you can end up with usable surfaces much faster

Take Advantage of the “One-Two Cleaning Punch”

The “one-two cleaning punch” refers to cleaning and then sanitizing. This is the best way to clean hard surfaces to stop germs, viruses, and bacteria from spreading. How well you can sanitize will depend on how well you have accomplished the first step – cleaning.

Once again, heat is important here. Cold water has been shown to have no impact on bacteria, while 140-degree water can reduce bacteria by 90%. When you get up to 176 degrees, bacteria colonies are reduced by 97% and 311 degrees will rid you of them entirely. Note as well that COVID-19 can be inactivated when exposed to a temperature of 133 degrees.

If you are ready to learn more about the many options available to you, we welcome your call to Pressure-Pro at 772-461-4486. With our years of experience, we can find the right choice for your needs.

Back to Basics: What is Bio Security and Why is it So Essential to the Agricultural Industry

There is a lot of talk of bio-security at the moment but many people are not clear on what it means, how to follow bio-security best practices, and why it is so important to the agricultural industry in particular. Read on to get the facts and contact Pressure-Pro at 772-461-4486 if you want to invest in a hot water pressure washer that can help you achieve your bio-security goals.

The Definition of Bio Security

At its base level, bio-security refers to a system of management practices designed to reduce the risk of introducing either new diseases or agents that could cause disease, to a farm or a stable. In the current conditions, in which people are understandably worried about safety in general but the safety of the food they are eating in particular, this is an important consideration for the agricultural industry.

The Main Goal of a Good Biosecurity Program

If you want the optimal biosecurity program, it will likely cover a number of things. That said, at the end of the day the most important thing should be addressing the prevention of diseases entering and spreading on a farm, in a stable, or even in a farm home. While the program can address other things, it is important to remember that this is the prime concern and goal.

Procedures Typically Associated with Biosecurity Plans

The procedures involved in any particular biosecurity plan will depend largely on the organization that is running the plan. However, common procedures we see and recommend include:

- Barn sanitation

- Transportation sanitation

- Rodent control

- Worker entry policies

- Visitor Worker polices

- General farm security measures

Again, these are just some of the procedures that are often looked at for a good biosecurity plan.

Prevention Isn’t the Only Factor a Biosecurity Plan Will Consider

While the ideal option is to prevent the disease from getting anywhere near your facility, a biosecurity plan should be taken into consideration that you may at some point deal with disease. That is why the plan should also work to prevent disease from spreading. If you have disease present in one segment, or even several segments of the herd, you can use biosecurity measures to prevent disease from spreading to other segments and causing more issues.

Biosecurity is Nothing New

While many companies are looking at their biosecurity practices in light of COVID-19, it has been an important factor to consider since the outbreak of Asian flu in poultry farming, and the outbreak of African Swine Fever in pig farming.

Biosecurity is a global issue that is best dealt with upfront and not avoided. If you have questions about what types of cleaning machinery can keep your facility as safe and sanitized as possible, we encourage you to contact Pressure-Pro at 772-461-4486 for help.

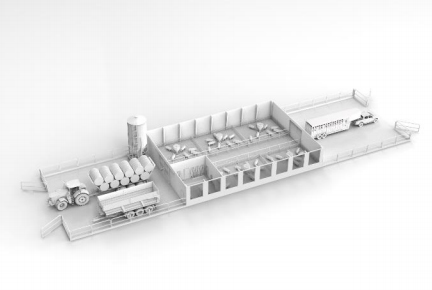

We’ve Got the Solutions for All Your Cleaning Needs: Learn more about cleaning and sanitizing equipment at IPPE 2020

If you’re looking for a line of high pressure washers, industrial vacuums or floor care machines specifically designed to clean and sanitize your equipment in the feed, meat and poultry industries, IPPE 2020 in Atlanta, GA is your go-to event from January 28-30.

If you’re looking for a line of high pressure washers, industrial vacuums or floor care machines specifically designed to clean and sanitize your equipment in the feed, meat and poultry industries, IPPE 2020 in Atlanta, GA is your go-to event from January 28-30.

While you attend, visit Nilfisk ISSA booth #7475 to preview our complete line of high pressure washers to keep your facility clean and sanitized.

Here’s a preview of what Nilfisk believes is “Better Cleaning” for your facility:

- Advenger X2805D-C Rider Floor Scrubber is easy-to-operate and is highly maneuverable available in three unique models — disc, cylindrical and our patented REV™ Technology — to meet any cleaning challenge and comes equipped with the green-cleaning EcoFlex™ System, to save you money on water and detergent while maximizing your runtime.

- ATTIX 19 AE Flood Sucker separates solids into a stainless-steel basket inside the canister while liquids are simultaneously discharged through a fire hose. The powerful discharge pump expels water up to 30 feet vertically and 15 feet horizontally. It can be operated in three modes — vacuum only, pump only, or vacuum and pump. Where ordinary sump pumps leave up to 1.5 inches of liquid on the ground, the Flood Sucker completely removes liquids, leaving a dry surface behind.

- Nilfisk MH 5M hot water pressure washer is a workhorse for cleaning direct food contact surfaces, from mixers to conveyors used in RTE food manufacturing facilities. To further protect the quality of the end-product as it goes out the door, high pressure washers are also commonly used to clean loading docks and delivery trucks.

Nilfisk experts will be available at booth #7475 to discuss specific applications and sanitizing challenges.

We look forward to seeing you there!